In recent years, the mining industry has faced increasing pressure to adopt more sustainable and eco-friendly practices. This shift is driven by a combination of regulatory requirements, community expectations, and the growing recognition of the environmental impacts associated with mining operations. Stakeholders, including investors and consumers, are increasingly prioritizing sustainability, pushing mining companies to innovate and implement greener practices to meet these demands.

Water plays a vital role in mining operations, serving various purposes such as mineral processing, dust suppression, and infrastructure cooling. Water in mining is exposed to various types of contamination, including algal blooms, which can lead to severe environmental and health hazards if not properly managed. However, managing water resources sustainably is a significant challenge.

LG Sonic’s innovative algae control is not only enhancing mining operations globally but has also shown remarkable results in gold mines. Effective water management is essential not only for operational efficiency but also for compliance with environmental regulations and the long-term sustainability of mining projects. Here, we present two cases where gold mines had different approaches to achieving these results.

Impact of Algae in Mining Operations: Challenges and Solutions

Algae in mining water bodies degrade water quality by increasing turbidity and organic matter, hindering filtration and treatment processes crucial for mineral processing. Additionally, algae accumulation in intake systems, settling ponds, and pipes causes clogging, necessitating frequent maintenance and increasing operational costs. Algae’s production of organic compounds can interact with mining chemicals, potentially altering process water composition and impacting mineral extraction efficiency.

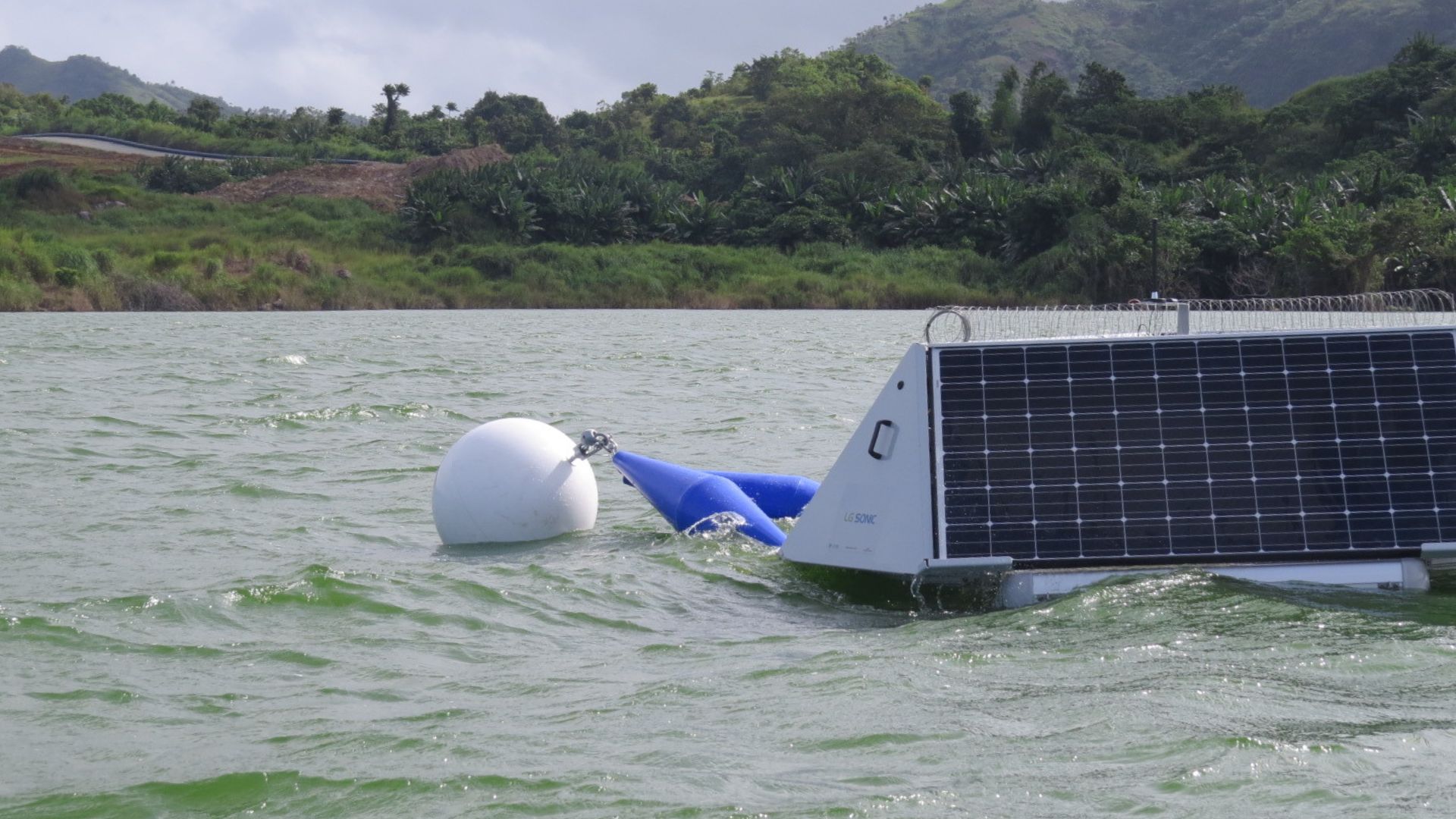

MPC-Buoy system tackles these challenges by employing ultrasound waves to eradicate up to 90% of algae. Our technology not only addresses existing algae problems but also prevents future algal blooms with real-time water quality monitoring, ensuring uninterrupted operations and saving both time and money. This ensures the continued high quality of water used in mining operations.

Case Study: Philippines Gold Processing & Refining Corp.

The largest gold mine in the Philippines, Phil. Gold Processing & Refining Corp. (PGPRC), faced significant operational challenges at the Masbate Gold Project (MGP) due to persistent algae growth. This issue required daily filter cleaning, which increased operational expenses, created inefficiencies, and made the water treatment process labor-intensive and costly. The algae problem led to frequent blockages in sand filters, necessitating extensive treatment before water could be reused or discharged.

PGPRC installed six MPC-Buoy systems from LG Sonic, to reduce maintenance activities and decrease the tailing dam’s operational costs, which amounted to millions at the time. These systems use ultrasound waves to target and eliminate algae without harming other aquatic life or releasing algal toxins.

Six months after installation, chlorophyll-a levels dropped from 200 mg/L to 1.2 mg/L. Due to effective algal management, water quality improved both prior to and following discharge treatment, while also reducing the need for filter cleaning.

Case Study: Golden Algae Control in Peru

In Peru, a major gold mine took a unique approach as part of its sustainability initiatives. This mine, one of the largest in South America, aimed to support the local community by maintaining a drinking water reservoir.

Our intervention with the MPC-Buoy system ensured clean water in the reservoir, benefiting over 5,000 families in the surrounding community. This effort not only maintained high water quality for drinking purposes but also reinforced the company’s commitment to social and environmental responsibility.

Conclusion

At LG Sonic, we are committed to helping gold mines go green by providing sustainable algae control solutions that enhance operational efficiency and support environmental compliance. Our interventions lead to significantly improved water quality, reduced maintenance needs, and smoother operations.

These results demonstrate the potential for advanced technology to support the mining industry’s efforts to adopt eco-friendly practices, contributing to a more sustainable future for both the industry and the communities it impacts. For more information on our projects and solutions, visit LG Sonic.